Evaporating Service : Refining Your Natural Extracts Through Efficient Solvent Removal

Amid fierce market competition, many businesses now focus on developing natural extracts for products in diverse sectors—health, dietary supplements, cosmetics, and high-quality agricultural goods. While effective extraction is a pivotal step, one often-overlooked yet critical phase is evaporating or solvent removal, designed to leave behind a concentrated, potent extract suitable for commercial product development.

Why the Evaporation (Solvent Removal) Step Matters

- Enhancing Extract Quality and Concentration

After extraction—whether using ethanol, methanol, water, or other solvents—the resulting mix still contains significant amounts of solvent and secondary plant compounds. Evaporating the solvent ensures that what remains is a concentrated, pure extract ready for incorporation into various commercial products.

2. Reducing Residual Solvents

Incomplete or improper evaporation can leave behind solvent traces that compromise product safety, especially in heavily regulated fields like cosmetics and dietary supplements. A dedicated evaporating service monitors and manages the solvent removal process to prevent contamination in the final product.

Principles of Solvent Selection & Boiling Points

1. Boiling Points of Common Solvents

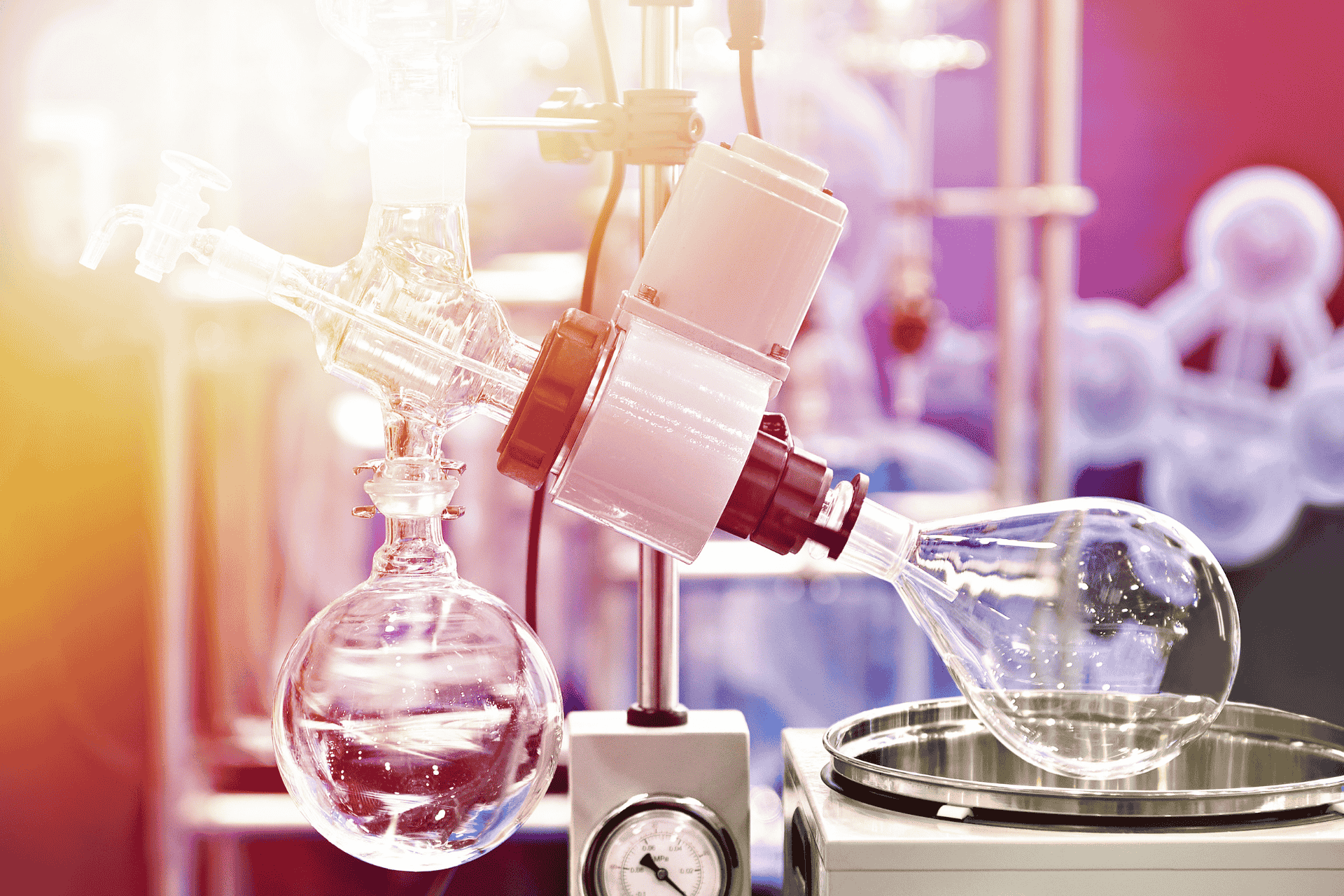

- Methanol (bp: 65°C)

- Highly polar, ideal for extracting phenolic compounds but more toxic. Must be removed rigorously.

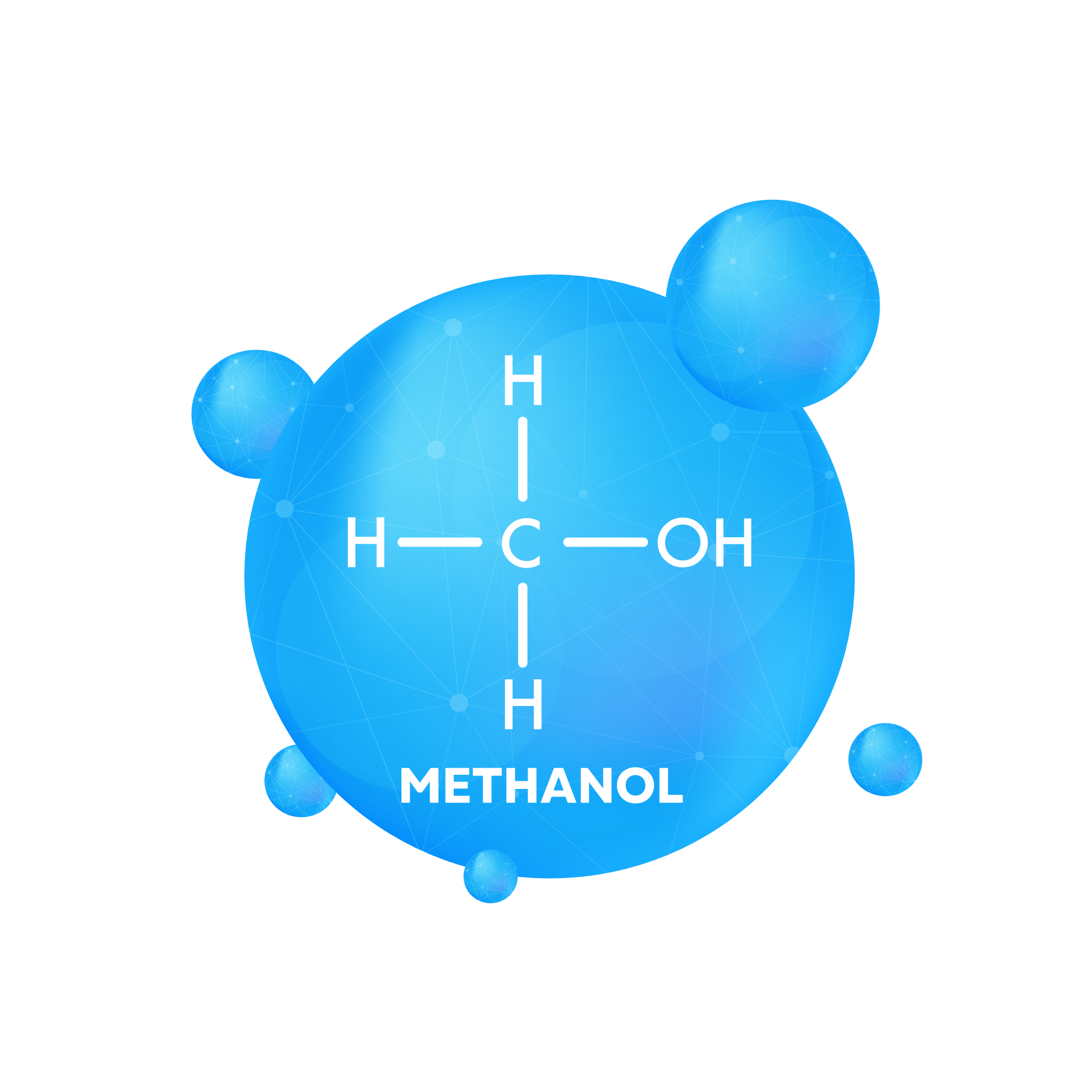

- Ethanol (bp: 78°C)

- Popular for herbal and natural extracts, lower toxicity relative to methanol, moderate boiling point for easier evaporation.

- Hexane (bp: 68°C)

- Non-polar, excellent for fat-soluble compounds. Highly flammable, requiring careful handling.

- Water (bp: 100°C)

- Safe for consumption but demands prolonged heating and meticulous planning to avoid thermally degrading sensitive actives.

2. Solute-Solvent Compatibility

Different compounds dissolve better in polar or non-polar solvents, making it essential to understand your target compound’s polarity, molecular weight, and sensitivity to heat/light when selecting a solvent.

3. Benefits of Low-Boiling-Point Solvents

Solvents like methanol or hexane evaporate quickly and at lower energy costs. This shortens evaporation time and reduces thermal damage to heat-sensitive compounds.

4. Precautions with High-Boiling-Point Solvents

Using solvents such as ethanol or water requires careful temperature and pressure management to preserve active compound integrity.

Therefore, choosing a solvent and understanding the boiling point of each solvent is a fundamental step that should be given great importance in order to obtain a concentrated and high-quality extract that meets market standards and consumer needs.

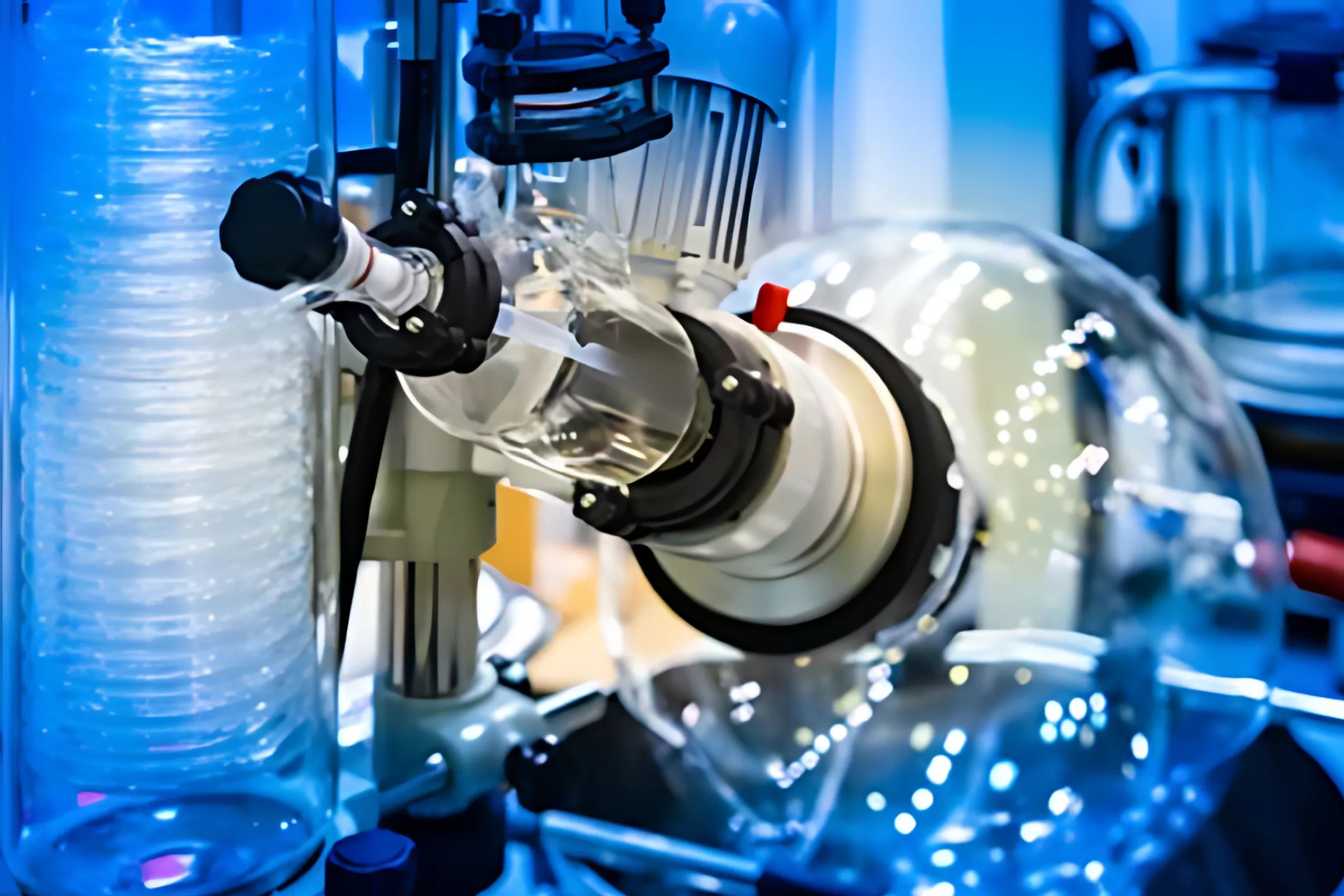

Rotary Evaporators in 1L, 20L, and 80L for Versatile Needs

To accommodate various production levels, we offer rotary evaporators (and other evaporating equipment) in 1L, 20L, and 80L sizes, each suited to different applications and raw material volumes:

- 1L Rotary Evaporator

- Lab-Scale R&D: Ideal for small-batch testing and formula optimization.

- Resource Efficiency: Limited material use and controlled solvent volumes reduce costs.

- 20L Rotary Evaporator

- Pilot-Scale: Bridges lab results and SME-level production, enabling extended testing without full industrial investment.

- Flexible Solvent & Temperature Controls: Handles diverse herbs, agricultural materials, and active compounds.

- 80L Rotary Evaporator

- Industrial-Scale: For large-volume extractions and continuous processing.

- Robust Safety & Consistency: Precise temperature and pressure controls, ensuring reproducible outcomes on a commercial level.

Why Choose TIBD’s Evaporating Service?

- Comprehensive, End-to-End Support

From raw material selection and extraction planning to evaporation and final extract quality checks, we provide an integrated workflow so you don’t have to juggle multiple service providers. - Rotary Evaporator Options for All Scales

Whether you’re a small enterprise or scaling up to industrial production, we have suitable evaporation equipment at lab, pilot, and industrial levels. - Expert Team & Professional Researchers

Our scientists and extraction specialists offer technical guidance on solvent choice, process design, and quality control to ensure premium extracts. - High Safety & Quality Standards

Operating under ISO and GMP guidelines, with partner labs for safety and contamination testing—ensuring final extracts meet rigorous market demands. - Cost-Effective Results

Proper rotary evaporation techniques help minimize the loss of valuable actives, giving your final product a competitive edge.

Evaporation: A Critical Step Toward High-Caliber Extracts

In extract development, evaporation (solvent removal) is key to achieving an internationally recognized standard. Understanding each solvent’s boiling point and polarity, designing the right extraction method, and using appropriately scaled evaporating equipment collectively pave the way for successful commercial and research outcomes.

When you combine scientific accuracy with robust management, your final extract emerges as a potent, pure concentrate—ready for supplements, cosmetics, or innovative products commanding a premium in global markets.

We’re here to advise on solvent selection, process design, multi-scale production planning, and delivering high-grade extracts end-to-end. Click here to learn more about our Evaporating Service and how we can help refine your extracts with confidence.