Freeze Drying Service

A New Dimension in Preserving High-Quality Raw Materials and Extracts

As the creation of natural-based products and herbal extracts becomes increasingly widespread—be it in dietary supplements, cosmetics, health beverages, or other innovative offerings—effective preservation and processing technologies that maintain the value of active compounds and extend shelf life are paramount. Beyond simply retaining the fresh taste, aroma, and color of your raw materials, robust preservation techniques also ensure consistent product quality that can confidently enter the market.

One technology currently capturing the attention of both industry and deep-tech R&D is freeze drying—often referred to as “freeze dry” or “lyophilization.” It stands out from more common drying methods like hot-air drying or microwave drying because it can retain physical properties, color, aroma, taste, and active ingredients with exceptional efficiency. This freeze drying service can elevate the quality of your products to surpass those of your competitors.

What Is the Freeze Drying Process?

Freeze drying removes moisture from products using the principle of sublimation, where ice transitions directly from a solid state to a vapor without passing through the liquid phase. This method’s primary strength lies in low-temperature processing, ensuring that heat-sensitive active compounds remain intact. As a result, the freeze dryer is widely embraced by manufacturers and researchers alike.

Key Stages of Freeze Drying

- Freezing Stage

- The raw material is brought below its freezing point until its liquid content turns to ice throughout.

- This step helps preserve cell structure and prepares the material for the sublimation phase.

- Primary Drying

- The system pressure is significantly lowered, and the temperature is adjusted to allow the ice within the material to sublime (change from ice to vapor).

- About 90–95% of the water content is removed at this stage.

- Secondary Drying

- The temperature is gently increased while maintaining low pressure to eliminate any residual moisture at a molecular level.

- The material ends up with an extremely low moisture content, ready for packaging and extended storage.

Highlights and Advantages of Freeze Drying

- Preserves Nutritional and Extract Value

- Low-temperature conditions keep active compounds, enzymes, and vitamins more stable than conventional drying methods.

- Minimizes nutrient loss, making it ideal for health-oriented products and supplements.

- Maintains Structure, Color, and Aroma

- With minimal heat usage, cell structures remain largely intact, preserving color, smell, and taste closer to the original.

- Enhances a premium, natural image—particularly important for upscale product lines.

- Extended Shelf Life

- Ultra-low moisture levels drastically slow microbial growth.

- Allows longer shelf placement without added preservatives or with significantly reduced preservative amounts.

- Lightweight and Easy to Transport

- Removing most of the water content creates a lighter product, reducing shipping and storage costs.

- Ideal for export markets and regions with long supply chains.

- Supports Research & Development (Deep Tech R&D)

- Perfect for studies requiring long-term preservation of extract properties or biological materials.

- Drives new innovations across food, pharmaceutical, and other advanced tech industries.

Who Benefits from Freeze Drying Services?

- New Brands and Entrepreneurs

- Looking to stand out in health products, dietary supplements, or herbal beverages.

- Freeze drying elevates product quality, reinforcing brand credibility.

- Community Enterprises

- Seeking to enhance local offerings—e.g., dried fruits or herbal products—to international standards.

- Contract freeze drying extends shelf life while maintaining authentic flavor and aroma.

- Premium Brand R&D

- Focused on nutrition, taste, and consumer safety.

- Ideal for testing new formulations using small-scale freeze dryers (lab scale) before scaling to full industrial production.

- Research Institutes and Scientists

- Need to store extracts or samples in a dried form for in-depth analysis or long-term effectiveness studies.

- Minimizes the risk of compromised active compounds due to moisture or degradation.

- Businesses Requiring Long-Term Shelf Stability

- Suitable for markets in remote areas or long-distance exports.

- Reduces transportation costs and mitigates product losses along the supply chain.

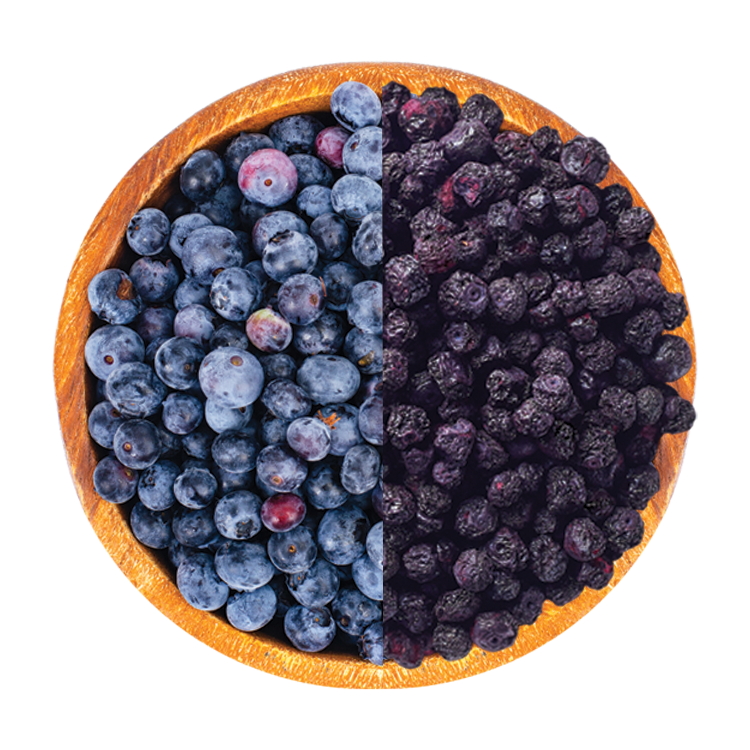

Samples of Before & After Freeze Drying

Freeze Drying Services Across Multiple Scales

Lab Scale

-

- Ideal for optimization tests and preliminary feasibility studies.

- Uses small freeze dryers, allowing precise control of temperature and pressure for best results.

- Enables thorough chemical, nutritional, or active compound analysis in limited quantities.

Pilot Scale (Semi-industrial level)

-

- Supports larger production batches, suitable for market testing or pre-commercial expansion.

- Lets you evaluate costs and refine formulations in near-industrial conditions, reducing long-term investment risk.

- Once pilot-scale success is confirmed, full-scale production can proceed with confidence.

Raw Materials and Solutions Best Suited for Freeze Drying

While freeze drying can apply to numerous materials, some types see the greatest advantages:

Herbal Extracts

Many herbs containing heat-sensitive active compounds benefit significantly from freeze drying:

- Turmeric Extract (Curcumin)

- Known for anti-inflammatory and antioxidant properties, freeze drying keeps these molecules intact.

- Centella Asiatica (Gotu Kola) Extract

- Valued for skin benefits and collagen stimulation; freeze drying preserves its active constituents for beauty product development.

- Pandan Leaf Extract

- Subtle fragrance easily lost to heat, but freeze drying helps retain its aroma and vibrant color.

- Other Thai Herbal Extracts

- Andrographis paniculata, lotus leaf, kaffir lime, etc., suitable for dietary supplements, cosmetics, and traditional medicines.

Vegetable & Fruit Extracts

Rich in vitamins and antioxidants, veggies and fruits greatly benefit from freeze drying, retaining color and nutritional value:

- Leafy Greens (spinach, ivy gourd, kale)

- High in vitamins A, C, and iron, freeze drying preserves nutrients better than heat drying.

- Citrus Fruits (lime, lemon, orange)

- High in citric acid and vitamin C; freeze drying keeps flavors and important compounds intact.

- Tropical Fruits (mango, banana, pineapple)

- Maintains taste and texture close to fresh produce, ideal for healthy product lines.

- Research-Oriented Produce (carrots, beets, avocados)

- Essential for retaining active properties in analysis or supplement development.

Protein Extracts

Dairy and protein-based products see notable advantages from freeze drying:

- Dairy Products (milk powder, cream powder, yogurt powder, cheese powder)

- Freeze drying retains flavor and molecular structure, beneficial in health-food manufacturing.

- Plant & Animal Proteins (whey, soy protein, corn protein)

- Maintains protein quality and water solubility, making it ideal for powdered supplements.

Freeze Drying Service is a key technology for elevating product quality and research applications in numerous fields—dietary supplements, cosmetics, herbal extracts, or even advanced agricultural processing to add value to local produce. Not only does freeze drying maintain nutritional and active properties efficiently, but it also lengthens shelf life, retains color, aroma, and taste similar to fresh materials, and reduces product weight for easier shipping.

Moreover, having a team of experts for designing experiments and analyzing results systematically allows entrepreneurs and community enterprises to strategize marketing efforts accurately, tapping into the full potential of their products. As a deep-tech process, freeze drying stands ready to set new benchmarks and elevate product or research standards above global market competition.

If you’re searching for a “freeze dry service” or “contract freeze drying” to enhance your products, extracts, or even research projects, reach out to us for initial consultation and a feasibility assessment of freeze drying. Click here to get started!