Solvent Extraction Service

Enhancing the Quality of Natural Extracts with Organic Solvents

From the food and beverage industries to cosmetics and dietary supplements, extraction—especially solvent extraction—is a critical method for efficiently isolating plant-based or herbal extracts. Using the right organic solvent (such as a suitable food-grade or commercial-grade solvent) can target compounds that don’t dissolve well in water (e.g., lipophilic or hard-to-dissolve active substances). While concerns about safety exist, a well-structured plan and careful solvent choice can yield high-concentration extracts that also meet strict safety standards—serving both research needs and industrial-scale production.

Understanding Solvent Extraction

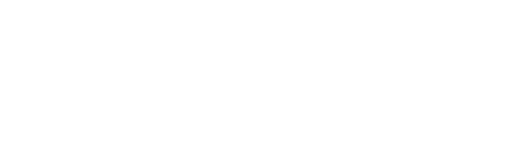

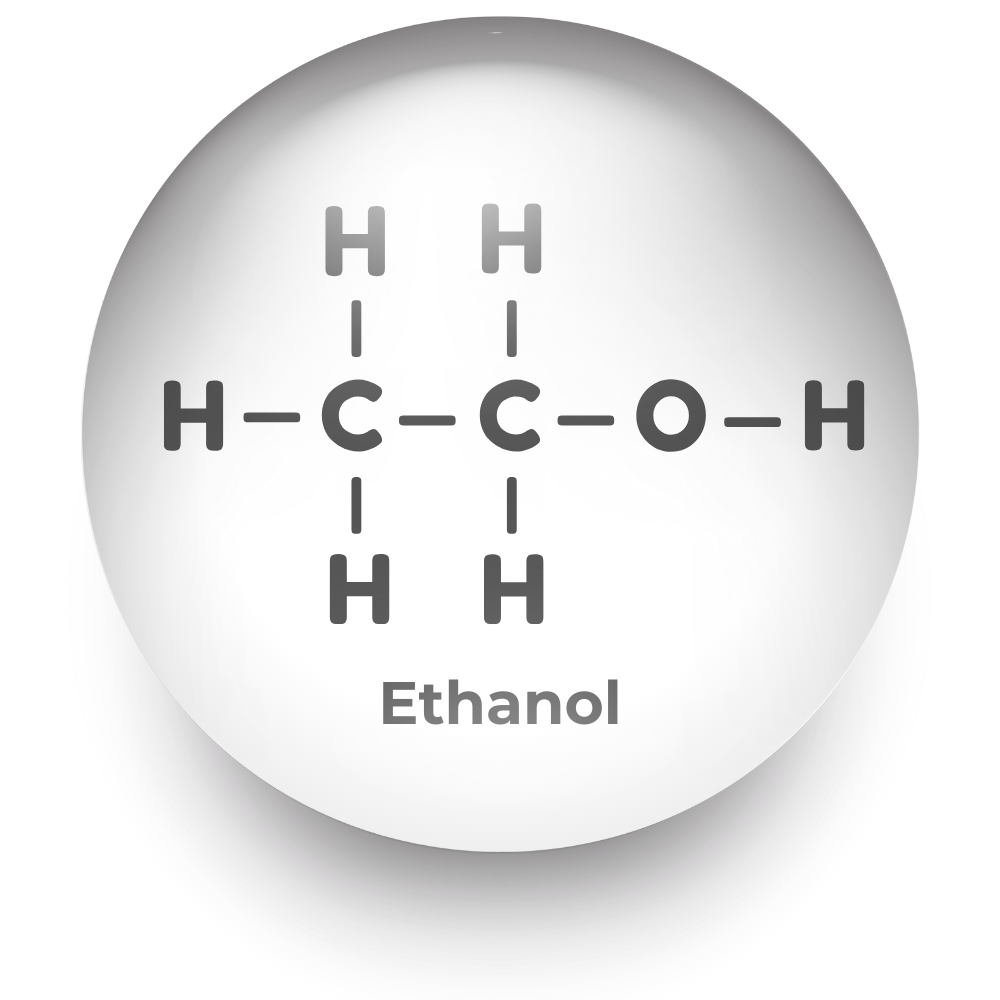

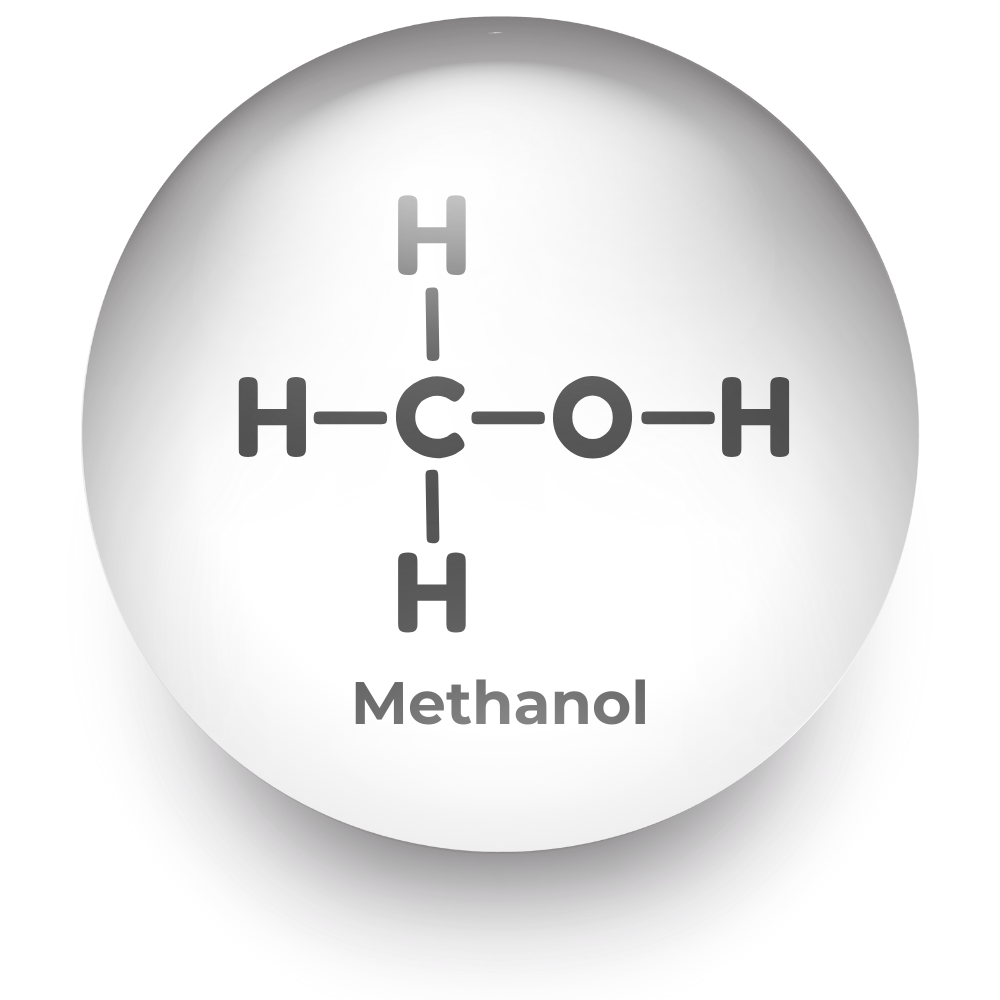

Solvent extraction hinges on the principle of “Like Dissolves Like,” meaning substances with a molecular structure similar to the solvent dissolve more readily. For instance:

- Non-polar substances dissolve best in non-polar solvents like hexane.

- Polar active compounds dissolve effectively in medium-to-high polarity solvents, such as ethanol or methanol.

Compared to simple water-based or traditional methods, solvent extraction can deliver higher extract yields more quickly. The key considerations are removing any residual solvent and controlling extraction conditions (time, temperature) to maintain product quality and safety.

Choosing the Right Solvent Grade: Food Grade vs. Commercial Grade

Selecting the solvent grade is just as crucial as the extraction process itself, particularly if the final product will be ingested or directly applied to the body:

Food Grade

- High purity standards, suitable for solvent extraction outcomes that will be used in food, beverages, or supplements.

- Strict controls on residual solvent levels, ensuring compliance with safety requirements.

Commercial Grade

- Suitable for R&D or general industrial uses where the final product may not be directly consumed.

- Lower cost, but still requires verification of contaminants and adherence to industry regulations on residual solvents.

If extracts are intended for foods or beverages, food-grade solvents provide added consumer confidence.

Ensuring Safety in Organic Solvent Extraction

While solvent-based plant extraction is vital, several safety issues must be addressed:

- Residual Solvent

- If solvent removal is incomplete, the extract may retain excess solvent beyond regulatory thresholds.

- Techniques like vacuum evaporation or drying are typically used to meet safety standards.

- Flammability & Toxicity

- Solvents like hexane or acetone are highly flammable, requiring robust storage and ventilation.

- Proper PPE (personal protective equipment) and safety measures are crucial in labs or production facilities.

- Regulatory Compliance

- Many regions set legal limits for residual solvents in food or cosmetics.

- Manufacturers must comply to avoid legal repercussions.

Common Solvents & Compatible Active Compounds

Below are examples of popular solvents used in solvent extraction, along with the types of compounds they target:

- Ethanol

- Medium polarity, suitable for flavonoids, antioxidants, and certain essential oils.

- Widely used in food, cosmetics, and supplements.

- Methanol

- High polarity, often used in research for alkaloids or phenolic compounds.

- More toxic than ethanol, making it unsuitable for consumable products.

- Hexane

- Non-polar, ideal for extracting fats and non-polar essential oils (e.g., in edible oil production).

- Requires careful handling due to flammability and residual concerns.

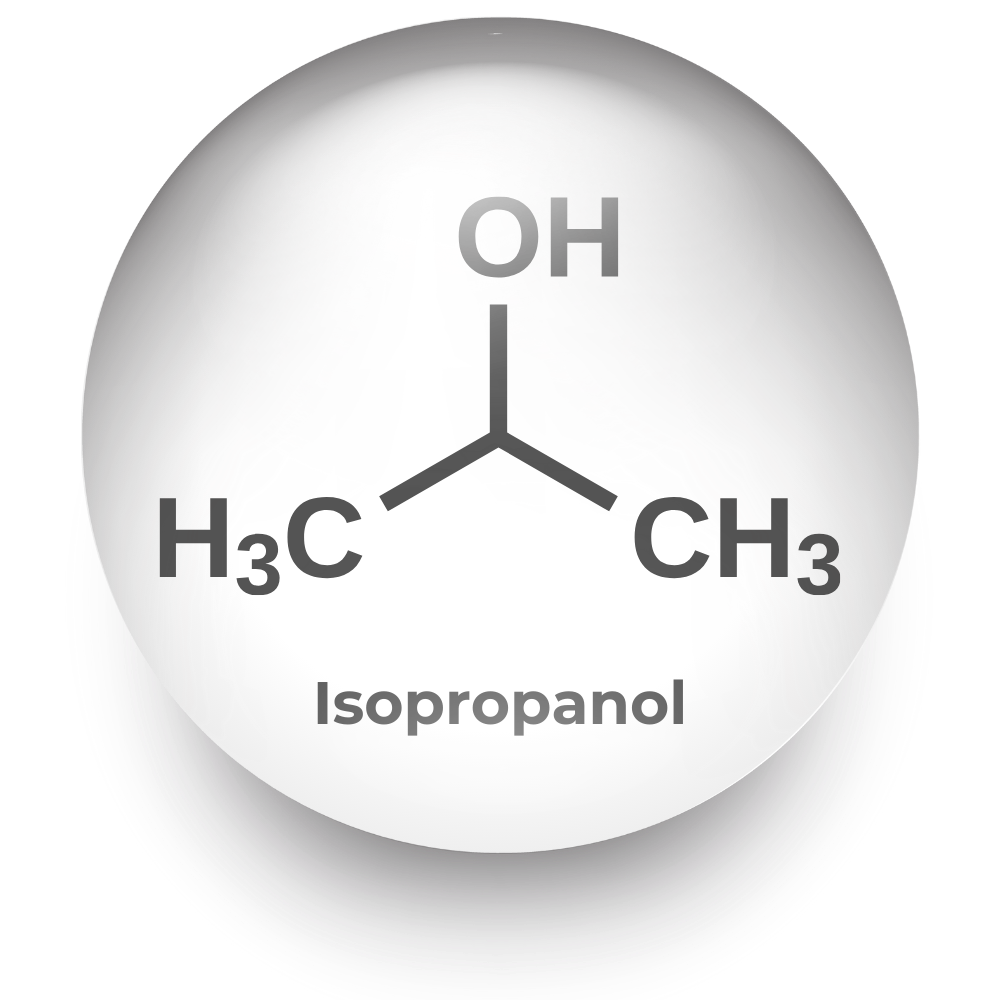

- Isopropanol (IPA)

- Medium polarity, dissolves compounds poorly soluble in water but soluble in alcohols (e.g., certain flavonoids).

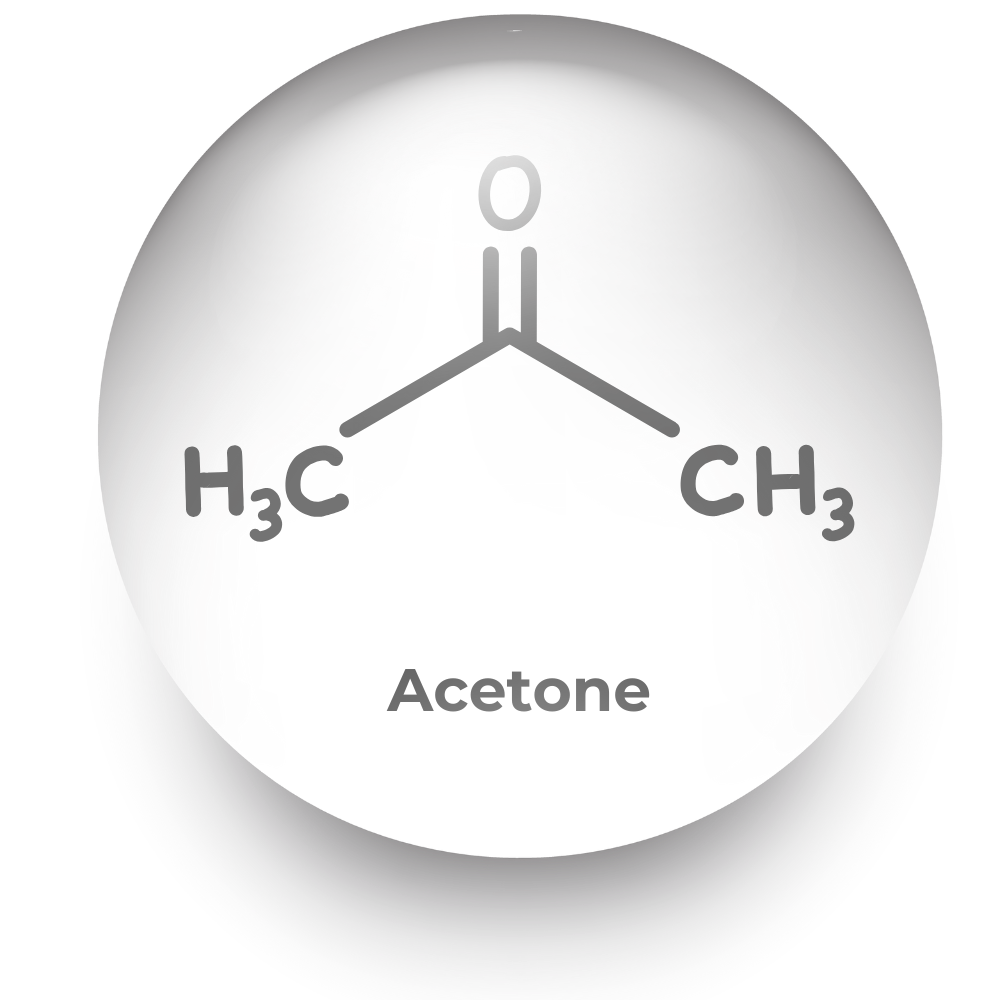

- Acetone

- Relatively high polarity, evaporates quickly with a pungent smell.

- Effective for phenolic compounds that don’t dissolve in water. Flammable, so must be handled with care.

Importance of Raw Material Preparation: Coarse vs. Fine Grinding

How you prepare your plant material significantly affects the efficiency of solvent extraction:

- Coarse Grinding

- Works well with longer maceration times, making it easier to filter out plant residue.

- Extraction can take longer to ensure full compound release.

- Fine Grinding

- Increases surface area for faster solvent penetration—useful in continuous extraction or centrifuge methods.

- Requires efficient solid-liquid separation to handle finer particles.

Benefits & Applications of Solvent Extracts

After obtaining high-quality natural extracts via solvent extraction, they can be utilized across multiple industries:

- Food & Beverage

- Natural flavor enhancers from herbal extracts or spices.

- Antioxidants and natural colorants extending shelf life and boosting product appeal.

- Cosmetics & Beauty

- Active compounds with anti-aging or anti-inflammatory properties.

- Plant extracts like essential oils or skin brightening agents.

- Food Supplements

- Bioactive concentrates with potent alkaloids, flavonoids, or phytochemicals.

Balancing Safety & Efficiency: Getting the Most Out of Solvent Extraction

Solvent extraction is pivotal for isolating certain plant or herbal compounds, particularly those that don’t dissolve well in water. By aligning solvent polarity and grade (food or commercial), you can yield safe, high-purity extracts. Meanwhile, raw material prep—whether coarse or fine grinding—is essential for optimal extraction efficiency and effective filtration.

Although some solvents pose fire or toxicity risks, solid technical planning and robust safety protocols ensure compliance with quality standards in food, beverage, cosmetic, pharmaceutical, or chemical sectors. This approach also meets the growing trend favoring natural extracts.

If you’re seeking a solvent extraction service, contact us. We offer full support—from initial planning to the actual extraction process—ensuring extracts meet your specifications, quality standards, and market needs, both domestically and internationally. Click here to learn more!