Soxhlet Extraction Service : A High-Efficiency, Semi-Continuous Method for Plant and Herbal Extracts

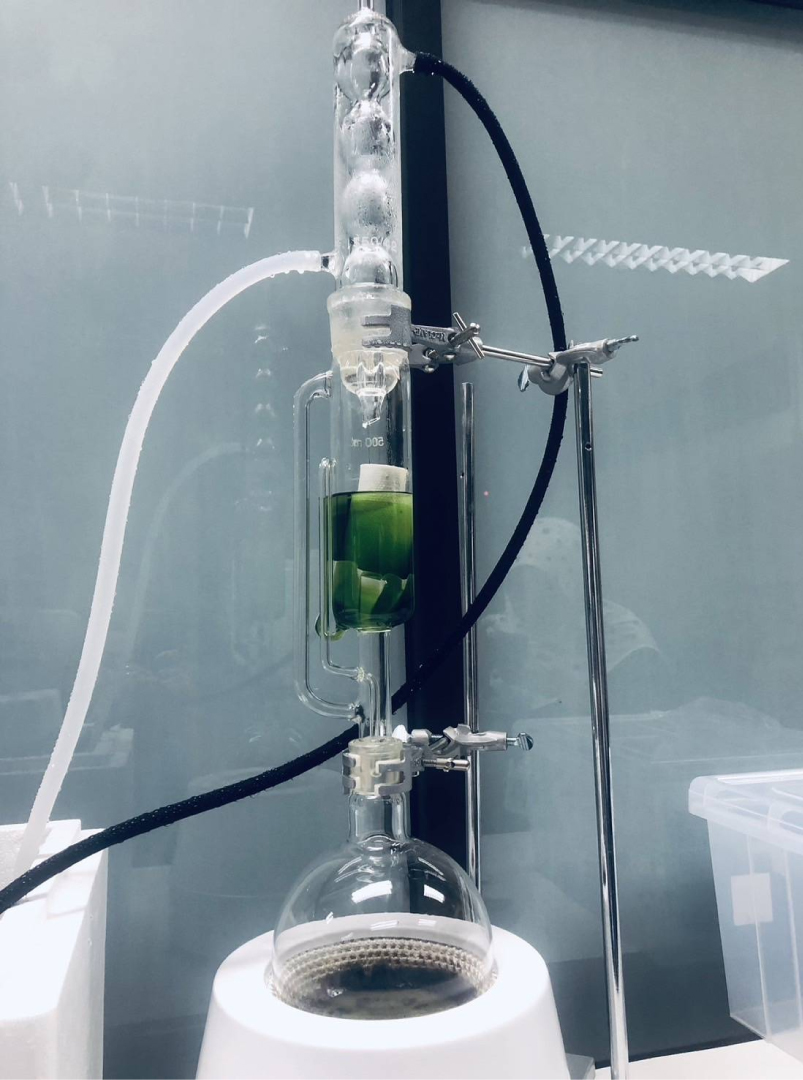

Understanding Soxhlet Extraction

Soxhlet extraction is a semi-continuous technique developed in 1879 by German chemist Franz von Soxhlet. It relies on distillation and condensation processes that repeatedly cycle a solvent through the raw material. This cyclical approach maximizes extraction of bioactive compounds—be they fats, essential oils, or other target substances. Widely used in both academic research and industry, Soxhlet extraction efficiently isolates the desired plant extract or active compound.

A Soxhlet apparatus typically includes a boiling flask (heat source), extraction chamber (containing the plant material), and a condenser (cooling column). The solvent is heated to vaporize, travels upward to the condenser, then condenses back into liquid, dripping onto the material in the extraction chamber. The solvent, now carrying dissolved extracts, returns to the boiling flask to repeat the cycle—hence “semi-continuous.” This method has long been a mainstay in scientific literature and industrial applications.

Advantages of Soxhlet Extraction

- Semi-Continuous Operation

- No need to constantly add fresh solvent since it recirculates in a closed loop

- Cost-effective use of limited raw materials, ideal for R&D settings or specialized extracts

- Ease of Control

- Adjusting temperature, distillation rate, or solvent polarity is straightforward

- Suited for laboratory-based formulation (R&D) and pilot trials

- High Efficiency

- Continual solvent reflow bypasses solvent saturation issues common in batch extraction methods

- Maximizes yield of targeted compounds from plant material

- Reduced Residuals

- Multiple extraction cycles thoroughly remove active compounds, minimizing leftover residue

- Ensures a more complete recovery of plant extracts

Key Factors in Solvent Selection & Process Control

While Soxhlet extraction is a semi-“automated” solvent recycling method, several core aspects should be addressed:

- Polarity Matching

“Like Dissolves Like” is essential: choose a solvent whose polarity aligns with your target compounds. Highly polar compounds (e.g., phenolics, flavonoids) often require methanol or ethanol, whereas non-polar substances (e.g., fats, essential oils) may need hexane or dichloromethane.

- Boiling Point

Selecting a solvent with a suitable boiling point optimizes both energy usage and distillation efficiency. A solvent that evaporates too quickly wastes resources; one that’s too high in boiling point risks degrading heat-sensitive compounds.

- Safety

Flammable solvents (e.g., hexane, petroleum ether) demand robust ventilation and spark-prevention measures. Food or pharmaceutical-grade applications may prefer ethanol for its safer profile, but it should meet food-safety standards.

- Raw Material–Solvent Ratio & Extraction Duration

Balanced raw material vs. solvent proportions and carefully timed extractions affect both yield and cost. Optimization ensures peak results while managing production overhead.

Pros and Cons of Soxhlet Extraction

Pros

- High Yield: Continuous solvent recirculation extracts compounds efficiently, preventing solvent saturation

- Solvent Savings: The closed-loop design uses and reuses the same solvent, lowering costs

- Scalability: Beginning with a lab-scale Soxhlet setup (feasibility testing) and expanding to industrial volume is straightforward

- Globally Recognized: Soxhlet extraction has extensive scientific references, widely accepted in research and industry

Cons

- Longer Processing: Compared to certain rapid extraction techniques

- Requires Cooling System: A condenser and temperature controls are necessary for effective distillation cycles

- Safety Concerns: Special precautions needed for flammable solvents or high-temperature systems

Which Compounds Suit Soxhlet Extraction?

Soxhlet extraction commonly targets compounds critical to pharmaceuticals, foods, cosmetics, or industrial applications—especially those soluble in organic solvents:

- Lipids & Oils

- Essential oils (e.g., aromatic plant oils), seed oils, or herbal lipids often best extracted with non-polar solvents like hexane or petroleum ether

2. Terpenes & Monoterpenes

-

- Aromatic molecules in plants such as mints (Mentha), cannabis (Cannabis spp.), or hops (Humulus lupulus)

- Dissolve effectively in organic solvents

3. Flavonoids & Polyphenols

-

- Bioactive plant compounds (in teas, fruit, herbal sources) where mixtures of ethanol, methanol, or water co-solvents can enhance extraction

4. Alkaloids

-

- For instance, caffeine from coffee/tea or other plant alkaloids. Solvent choice depends on each alkaloid’s chemistry

5. Resins & Certain Polysaccharides

-

- Oleoresins in turmeric, black pepper, capsicum benefit from repeated solvent cycles, ensuring thorough extraction

Looking for a High-Quality Soxhlet Extraction Service?

TIBD offers a turnkey Soxhlet extraction service at laboratory and semi-industrial scales, covering:

- Raw Material Preparation: Cleaning, cutting, grinding to increase surface area

- Solvent Selection: Polarity matching for optimal yield and purity

- Extraction Process: Monitoring parameters (temperature, time, reflux rate) for your target outcome

- Extract Quality Analysis: Chemical profiling with instruments like HPLC, GC-MS, LC-MS, ensuring your plant extracts meet desired standards

Why Soxhlet Extraction Works for Both Research & Industry

- Flexible Solvent Choice

- The distillation-condensation mechanism accommodates various polar and non-polar solvents, ideal for multiple plant or chemical extractions

- Lab to Industrial Scale

- Pilot setups are perfect for feasibility testing prior to scaling up to semi-industrial or full production, serving academia and commercial enterprises

- Long-Term Cost Savings

- While initial capital outlay may be higher, efficient solvent reuse and high extraction yields reduce overall production costs

- Superior Compound Recovery

- Repeated solvent cycling extracts more robustly than maceration, leading to better yields of desired actives

- Trusted, Standardized Method

- Soxhlet extraction has long-established credibility in academic literature and broader industry, recognized as a solid, reliable approach

Soxhlet extraction is a high-efficiency, semi-continuous method for isolating important plant or herbal compounds. Its benefits—like solvent savings, ease of control, and strong yields—fit both lab research and industrial production. However, extracting maximum value also demands careful solvent selection and attention to safety. When performed properly, Soxhlet extraction preserves extract quality and potency, satisfying market needs for pure, bioactive ingredients over the long term.

If you seek a Soxhlet extraction service backed by complete technical support, TIBD stands ready to help. Contact us to discuss tailored solutions, from raw material prep through process planning, ensuring your extracted actives meet rigorous quality demands and consumer appeal. Click here