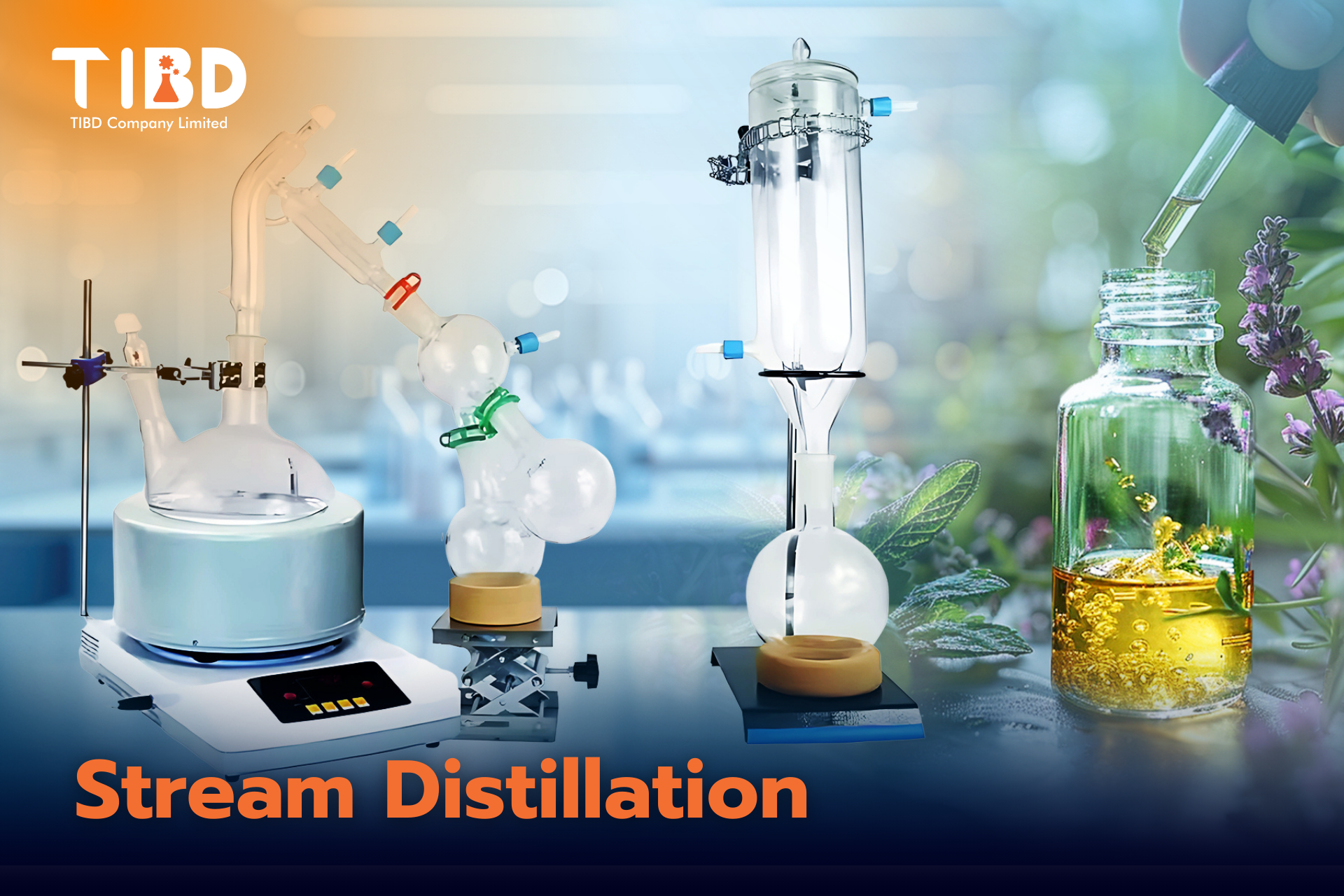

Stream Distillation Service

As demand for plant- and herb-derived extracts continues to surge—particularly in cosmetics (beauty), nutraceuticals (food supplements), and health & wellness products—finding the most suitable distillation or extraction technique is more critical than ever. Modern consumers value natural ingredients and insist on safe, high-quality products. One extraction method widely acclaimed for essential oils and other heat-sensitive, volatile compounds is steam distillation. It not only preserves the chemical structure and properties of key compounds but is also environmentally friendly, as it requires no harsh solvents that might leave harmful residues.

The Essence of Essential Oil Extraction: Understanding Steam Distillation

Steam distillation uses heat from steam and controlled pressure to release volatile compounds found within plants and herbs. The process hinges on the principle that steam can carry both volatile substances and essential oils out of the plant material. After the vapor cools and condenses, the essential oil naturally separates from the water.

Consequently, steam distillation typically yields two primary components:

- Essential Oil

- A concentrated blend of highly potent compounds, prized for its distinctive aroma and specific chemical properties.

- Commonly used in beauty products, dietary supplements, spa treatments, and a wide range of industrial applications.

- Hydrosol (Floral Water)

- The water portion, lightly aromatic due to water-soluble volatile compounds.

- Often incorporated into skincare and cosmetic products seeking a mild, natural scent.

Because steam distillation does not subject extracts to excessively high temperatures nor use chemical solvents, key compounds remain largely intact, and there is minimal risk of residual contamination in the final product. This method meets rigorous safety and purity standards favored by many industries.

Ideal Raw Materials: Herbs, Flowers, and Fruit Rinds for Steam Distillation

Steam distillation or steam extraction excels when working with materials rich in naturally occurring essential oils or volatile compounds. Typical raw materials include:

- Aromatic Herbs

- Examples: Basil, mint, rosemary, lemongrass, ginger, and turmeric.

- The volatile elements carry fragrance, flavor, and potentially therapeutic properties (e.g., antibacterial or anti-inflammatory).

2. Flowers

-

- Examples: Rose, jasmine, lavender.

- Extracted essential oils are vital in premium perfumery and high-end cosmetics.

3. Barks & Resins

-

- Example: Cinnamon bark, famed for its warm, spicy aroma.

4. Citrus Peels

-

- Examples: Orange, lime, lemon.

- Zesty essential oils used to enhance flavors in foods/beverages or to create fresh-scented cleaning products.

Sourcing plants from reliable environments—preferably organic and free of chemicals—ensures a high-quality final extract suitable for global market standards.

Why Steam Distillation Is the Preferred Method in Extract Industries

- Preserves Active Compounds

- Steam’s moderate temperature range helps maintain the structure and potency of key compounds more effectively than some other high-heat methods.

- Solvent-Free

- No harsh chemical solvents are used, eliminating concerns about toxic residue.

- Perfect for product lines emphasizing natural or organic positioning.

- Eco-Friendly

- Relies solely on steam-generated heat, minimizing pollutants and waste.

- High-Purity Extracts

- While the yield can be lower than solvent-based methods, the resulting oil is exceptionally pure and aromatic—ideal for premium goods.

- Versatile Production Scale

-

- Can be carried out at lab size for research, pilot scale for mid-level testing, and full industrial scale using steam distillers—adapting to evolving business needs.

Adding Value: Harnessing Steam Distilled Extracts for Food, Beauty, and Wellness

Once you’ve steam-distilled your essential oils, they can be utilized across various sectors:

- Cosmetics & Skincare

- Integrate into creams, lotions, serums, toners, or cleansers for a gentle natural fragrance and beneficial skin properties.

- Food & Beverage

- Many essential oils can enhance flavor or aroma, helping your products stand out in a crowded market.

- Health & Wellness

- Certain oils exhibit antibacterial, antioxidant, or calming effects—ideal for therapeutic or wellness-oriented product lines.

- Spa & Massage

- Essential oils blended with carrier oils for body treatments; or hydrosols for facial steams, adding hydration and relaxation benefits.

- Perfume Industry

- Intensely aromatic extracts from flowers or specific woods can serve as signature notes in upscale fragrances.

Tips for Selecting & Preparing Raw Materials: The Key to Premium Extracts

Quality extraction starts with quality raw materials. Successful steam distillation depends on choosing the right plant varieties and carefully managing cultivation and harvest:

- Variety Selection: Opt for plants with adequate essential oil content tailored to your final product goals.

- Growing Environment: Maintain consistent soil, water, and sunlight. Stable conditions help plants develop robust active compounds.

- Harvest Timing: Collect materials at peak essential oil concentration—e.g., mint leaves in the morning, or rose flowers when they are just fully opened.

- Pre-Distillation Prep: Some materials may be lightly dried or coarsely ground for better steam penetration. However, excessive heat or moisture could degrade key compounds

Cost-Effective Scaling: From Lab to Pilot Production

Many businesses begin with lab-scale experiments—comparing different plant varieties, adjusting formulas, and verifying results. Once a method proves viable, they progress to pilot-scale production. This phased approach allows fine-tuning parameters (e.g., temperature, timing, and pressure) for optimal essential oil yield without large, upfront investment.

- Lab Scale: Research and Development (R&D)—testing plants’ volatile profiles, formulating early prototypes.

- Pilot Scale: Detailed cost analysis and near-commercial runs. Identify break-even points, refine processes, and get real-world data for future expansion.

Consultants and experts can help manage expenses at every step—from raw material procurement strategies to the steam distiller operating costs—ensuring efficiency as you scale up.

Quality Assurance: Elevating Your Steam-Distilled Extracts’ Market Credibility

Even with a pure, aromatic steam-distilled extract in hand, proving its quality is essential:

- Purity Tests

- Instruments like GC-MS (Gas Chromatography-Mass Spectrometry) or HPLC confirm the presence of desired components and detect any undesired contaminants.

- Organoleptic Evaluation

- Experts assess aroma, color, and concentration—verifying consistency with industry standards.

- Stability Testing

- Determines how extracts react to heat, light, and humidity, establishing accurate shelf-life projections.

- Safety Assessments

- For any product requiring irritation or allergen screening (e.g., cosmetics, ingestible supplements), certified labs can conduct specialized analyses.

Why Choose Us: Building Confidence in Steam Distillation

Partnering with an experienced and knowledgeable team makes all the difference:

- Expert Researchers & Technicians: Skilled in steam distillation from lab-scale experiments to pilot-scale feasibility.

- One-Stop Service: From raw material selection, distillation trials, analytical testing, to marketing strategies—everything under one roof.

- Global-Standard Facilities: Our distillation setups and labs meet recognized certifications, ensuring top-tier safety and quality checks.

- After-Sales Support: Ongoing process optimization, scaling guidance, and compliance updates for environmental and safety regulations.

- Customizable Solutions: We adapt services and timelines to fit your business size, budget, and schedule.

Inspiring Innovation: Real-World Applications of Steam Distillation

Industries worldwide continue exploring new, value-added products using steam-extracted essential oils:

- Local Herbal Oils: Distilled from indigenous plants to support community farmers while producing signature scents.

- Clean Beauty Formulations: Crafting “green” cosmetics without harsh chemicals—featuring essential oils derived via steam distillation.

- Organic Health Products: Leveraging the potent active compounds in steam-distilled extracts for superfood blends or therapeutic items.

Riding the wave of “Natural & Organic” consumer demand, the market potential for steam-distilled products steadily rises. Businesses that plan carefully and invest in top-quality processes often reap strong market credibility and financial returns.

Steam Distillation represents a crucial step for anyone seeking to develop natural, high-standard products. By preserving the essential chemical structures without using solvents, it aligns perfectly with brands aiming to emphasize purity and safety at an international level.

Our steam distillation services encompass end-to-end support—plant selection, pilot-scale and lab-scale distillation, plus rigorous quality and safety checks. We strive to help you create standout products, earn consumer trust, and compete successfully in today’s marketplace.

If you’re in search of a “Steam Distillation Service” to produce premium-grade essential oils or volatile extracts, contact us today. Backed by a knowledgeable team, internationally certified equipment, and a broad network of collaborators, we’ll assist you in designing and executing the distillation process that grants you a market edge.

Click here to request an initial consultation or quote!