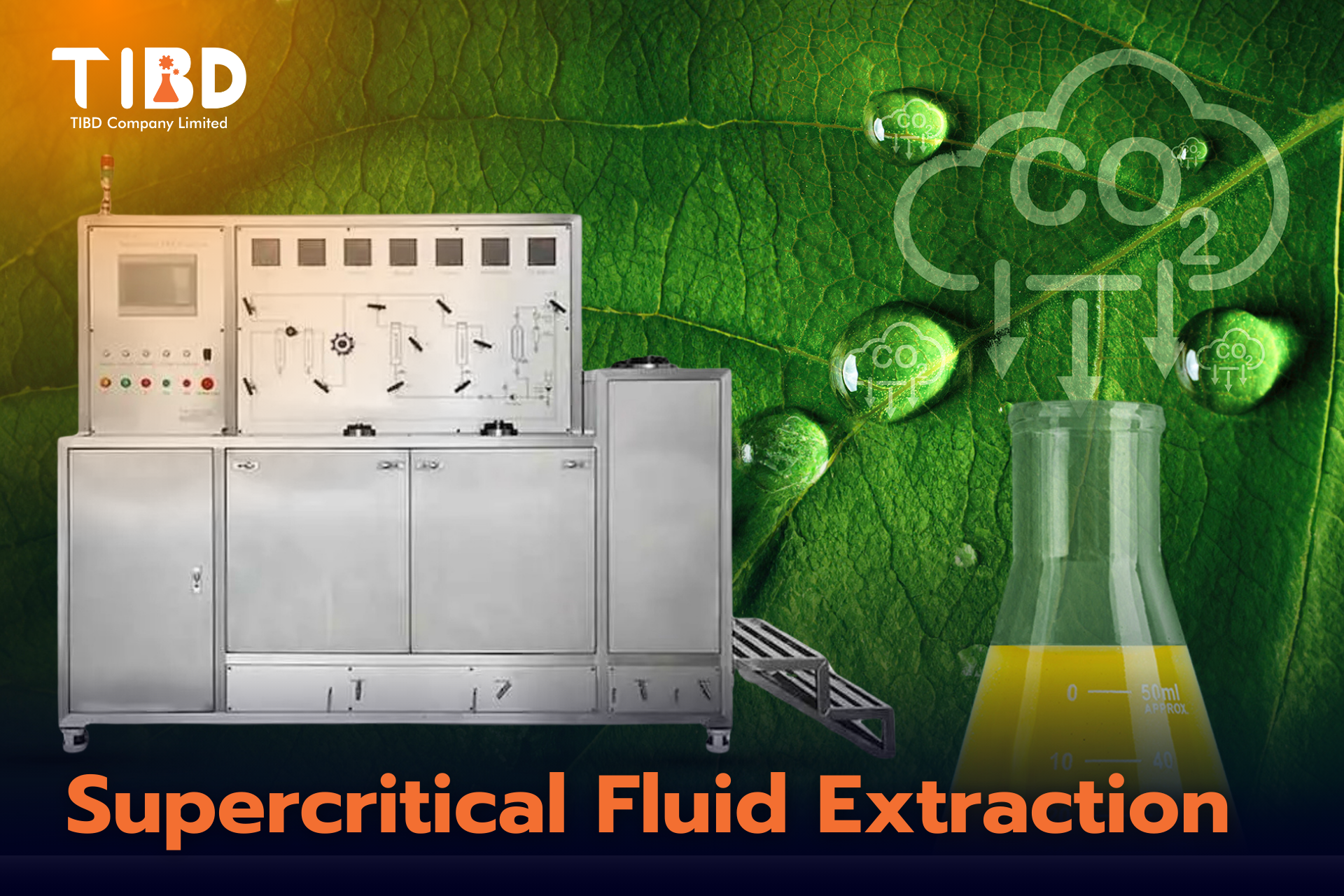

Supercritical CO2 Extraction Service

Elevate Your Business with High-Quality, Environmentally Friendly Natural Extracts

Growing demand for premium natural extracts in cosmetics, dietary supplements, and health products calls for safe, high-standard, and eco-friendly manufacturing. Supercritical CO2 extraction (also known as CO2 extraction) is a breakthrough method that meets these needs. By harnessing carbon dioxide in a supercritical fluid state, this technique delivers exceptionally pure extracts that preserve valuable bioactive compounds—without harsh solvents or high temperatures.

This article explores the core principles of CO2 extraction, its superior benefits over other extraction methods, and the advantages of partnering with a supercritical fluid extraction service. From conceptualizing formulas to industrial-scale production, our goal is to guide you toward producing premium extracts that resonate with consumer demand for safety, sustainability, and quality.

Why Choose Supercritical CO2 Extraction?

- Safe & Environmentally Friendly

Supercritical fluid extraction leverages CO2 under high pressure and temperature—above its critical point—creating a fluid with a density akin to a liquid yet able to diffuse like a gas. This drastically reduces (or eliminates) the use of harsh chemical solvents, enhancing worker safety and consumer health.- Minimal Environmental Impact: CO2 can be reclaimed and recycled, generating negligible toxic waste compared to solvent-based extraction methods.

- Eco-Conscious Appeal: The near-total avoidance of dangerous chemicals aligns with global trends favoring sustainability.

2. Preserves Active Compounds

A major challenge when extracting plant-derived actives is maintaining compound stability. By operating at relatively low temperatures, supercritical fluid extraction avoids degrading heat-sensitive bioactives. This ensures a higher-quality extract retaining chemical structures and functional potency better than other high-heat or solvent-heavy processes.

-

- Flexible Parameters: Operators can fine-tune pressure, temperature, and flow rate to selectively isolate target compounds (e.g., essential oils, antioxidants).

- Purity & Minimal Contaminants: The process can also reduce undesired elements like chlorophyll or unwanted odors, resulting in a cleaner, more marketable extract.

3. Highly Adaptable Conditions

Supercritical CO2 technology allows you to adjust extraction parameters—temperature, pressure, flow—to selectively capture specific components. This capability streamlines:

-

- Targeted Extractions: Whether aiming for essential oils, antioxidants, or medicinal compounds.

- Scalable Production: Suitable for lab-scale R&D, pilot-scale expansions, and industrial-scale operations.

Principles & Efficacy of CO2 Extraction

- How Supercritical Fluid Extraction Works

- Supercritical State:

Under appropriate high pressure and temperature, carbon dioxide transitions into a supercritical fluid—exhibiting liquid-like density with gas-like diffusion. This penetrates plant material efficiently to dissolve desired compounds. - Flexible Extraction Parameters:

By adjusting temperature, pressure, and flow rates, co2 extraction can selectively isolate various groups of actives—such as essential oils or antioxidants—each requiring unique conditions.

2. Superior Performance

- Minimal Organic Solvents:

Relying primarily on CO2 means little to no hazardous solvent residue in the final product—ideal for reducing toxicity and environmental impact. - Gentle on Sensitive Compounds:

Lower operating temperatures minimize damage to delicate ingredients. This makes supercritical fluid extraction well-suited for high-value, heat-sensitive actives. - High-Purity, Safe Extracts:

Extracts obtained via CO2 extraction often exhibit low impurities and can be refined to remove undesired color or odor components. By design, it eliminates complex solvent removal steps, saving time and resources.

Compounds Suited for Supercritical CO2 Extraction

CO2 extraction effectively targets fat-soluble (lipophilic) or semi-lipophilic substances due to supercritical CO2’s liquid-like density and gas-like penetration. Commonly extracted compound types include:

- Essential Oils

- Rich in terpenes (monoterpenes, sesquiterpenes), found in flowers, fruits, and aromatic herbs.

- Example: Lavender essential oil containing linalool and linalyl acetate.

2. Antioxidants

-

- Polyphenols (flavonoids, tannins, phenolic acids) that are heat-sensitive and degrade under harsh conditions.

- Carotenoids (beta-carotene, lycopene, lutein) dissolve well in fat and require gentler extraction methods.

3. Fatty Acids & Sterols

-

- Mono- and polyunsaturated fatty acids, plus sterols like β-sitosterol—beneficial in health supplements, cosmetics, and skincare.

4. Specialized Bioactive Compounds

-

- Anti-inflammatory or antibacterial agents typically found in herbs like turmeric (curcumin).

- The gentle nature of supercritical CO2 preserves these delicate compounds.

Advantages of CO2 Extraction in Terms of Quality & Environment

- No Residual Solvents

Carbon dioxide leaves behind no harsh chemical traces. Final products are safer for consumers—vital for stringent industries like supplements and cosmeceuticals. - Environmentally Responsible

CO2 is recyclable, producing minimal pollution. This green manufacturing approach supports ecological objectives. - Safe for Producers & End-Users

Reduces exposure to toxic or flammable substances, benefiting both factory workers and consumers concerned about chemical residue. - Fractionation & Dechlorophyllation

Adjusting pressure/temperature in supercritical co2 can remove undesired pigments (e.g., chlorophyll), delivering purer extracts meeting market preferences.

Key Benefits of Supercritical CO2 Extraction

- High-Quality Final Product

The extracts retain maximum potency and purity—ideal for industries requiring rigorous standards (dietary supplements, cosmeceuticals, health products). - Reduced Chemical Residue

Lacking harsh organic solvents significantly decreases contamination risk, meeting consumer demand for healthy and eco-friendly products. - Value-Add to Local Herbs

Regions abundant in medicinal plants gain competitive advantage by applying CO2 extraction to develop premium, export-grade products.

Comprehensive CO2 Extraction Support: From R&D to Industrial Production

Many companies lack expertise or specialized equipment to run supercritical co2 processes in-house. Working with a CO2 extraction service accelerates product development and yields results superior to trial-and-error methods.

Extraction Design & Formulation

- Analyzing Plant Material: Experts assess which raw materials are best suited for particular pressures and temperatures to maximize yield and quality.

- Tailoring Product Goals: Once the extract is concentrated and high-quality, specialists help you formulate products (texture, fragrance, color, bioactivity)—be they creams, serums, supplements, or other health items.

Quality & Industrial Standards

- Purity & Active Compound Testing:

Confirm concentration and absence of contaminants via HPLC or GC-MS for precise compositional insights. - Scaling Up:

Moving from lab-scale success to pilot or industrial scale requires engineering know-how, plus GMP or ISO compliance. Professionals guide equipment selection, process optimization, and quality controls.

Why CO2 Extraction is Worth the Investment

Elevated Product Standards

SMEs, community enterprises, research institutes, or large businesses can all harness supercritical fluid extraction to produce top-tier extracts matching eco-friendly and safety demands.

Differentiation in a Competitive Market

Marketing “CO2-extracted” labels underscores professionalism, innovation, and environmental care—key selling points for today’s conscious consumer.

Long-Term Savings & Risk Reduction

While supercritical CO2 equipment can be expensive upfront, reducing solvent-removal steps, robust machinery, and consistent product quality yield higher returns and expanded markets.

If you’re seeking efficient, eco-friendly methods to isolate potent bioactives from diverse herbs or plants—supported by modern supercritical fluid extraction equipment and an expert team—or want guidance on raw material selection, extraction techniques, cost planning, or industrial-scale production, click here to get started.